Steps for Cleaning and Lubricating Bearings

Regularly maintaining cleanliness and lubrication of your bearings is crucial for top-notch performance. Doing so not only extends the lifespan and robustness of your bearings but also maximizes their speed.

Important: Steer clear of water & sand

Exposing or storing bearings in damp and dirty conditions significantly reduces their lifespan.

Guide to Clean and Lubricate Bearings on Skates, Skateboards, and Scooters

Step 1

You will need: A cleaning agent such as a grease-dissolving liquid like Fluid wash, a waterproof jar, a drawing pin or box cutter, a small brush, and fresh oil/grease.

Detach the bearings from the wheel. Refer to the YouTube video above for instructions on removing the bearings from a wheel. The demonstration is on a skate, but the method is identical for skateboards and scooters.

Remove the wheels and extract the bearings.

Step 2

Clean the outer surfaces of the bearings using the brush to ensure all dirt is completely removed.

Bearings come in two types for maintenance: open and closed. Open bearings are easy to manage, while closed bearings can be maintained by carefully taking off the shield.

Clean the exterior of the bearings.

Step 3

If your bearings are sealed, the seal can be taken off using a drawing pin.

Certain closed bearings with metal shields include a small C-clip securing them. This C-clip needs to be removed with the drawing pin before you can remove the shield.

Don’t forget to also clean the seals and any provided C-clips.

Seals (without C-clip) are taken off from the bearing using a drawing pin or box cutter.

Step 4

Submerge the bearings in a sealed container with the cleaning agent, then shake it for a few minutes. This action will help dissolve any accumulated grime.

First, scrub the bearings using a small brush before applying the cleaning agent.

Step 5

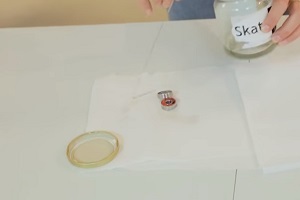

Take the bearings out from the container and eliminate any remaining cleaning agent by spinning the bearings. An air compressor can also be used to blow out the fluid. Set the cleaned bearings on a piece of clean cloth or kitchen tissue.

Bearings as they come out of the container with the cleaning solution.

Step 6

Verify the success of the cleaning procedure. Take the bearing by the inner ring and lightly spin it. If it doesn’t spin freely or if a crunchy noise is heard, the cleaning wasn’t sufficient. In such cases, repeat the cleaning using fresh cleaning agent. Extremely dirty bearings may require 2-3 repetitions of this process.

Confirm thorough cleaning of the bearing by giving it a spin.

Step 7

Position the bearings back onto the clean cloth or kitchen tissue. They are ready for oiling or greasing. Apply 1-2 drops of oil (avoid excess as it may attract dirt) or evenly spread 3 mm of grease inside the bearing.

Ensure the oil/grease is well dispersed by spinning the bearings. A drill machine can be used effectively for this purpose.

Carefully drip 1-2 drops of oil into the bearing.

Step 8

Finally, reinstall the shields onto the bearings and fit the bearings back into the wheels of skates, skateboards, or the pro scooter.

Replace the seals on the cleaned and lubricated bearings, and then place the bearings back onto the wheels.

Post-Cleaning and Lubrication

Once you've cleaned and lubricated the bearings, some distance may need to be covered before the oil/grease is evenly dispersed, thus allowing the bearings to achieve optimal performance.