Bearings Purchasing Guide

Confused about which bearings to choose? This guide clarifies essential terminology and facts about bearings. It will also outline which bearings best suit your specific style of riding or skating.

1. Overview of Bearings

Each wheel requires two bearings to function smoothly on the axle. The type of bearing greatly affects both speed and the overall sensation of your ride or skate.

Regardless of the type of bearing in use, avoid exposing them to sand, water, or humid conditions, as these drastically reduce their lifespan. Regular cleaning and lubrication of bearings can help extend their durability and improve speed. See how to clean your bearings here.

A spacer is also needed to fill the gap between the bearings, which prevents damage and ensures smooth rotation when axles are tightened. The spacer size will depend on the axle size in use.

8 mm spacer

6 mm spacer

Several factors contribute to bearing quality:

- Material

- Precision (ABEC)

- Lubrication

- Sealed or open (Removable Shield)

Identifying the ideal type of bearing for you:

- If you're primarily riding/skating outdoors, sealed bearings with grease are recommended,

since these resist dirt & dust effectively and require minimal maintenance. - If indoor riding/skating is your focus, opt for open bearings that allow fast spinning and easy cleaning.

- For speed enthusiasts or long-distance skaters, high precision bearings lubricated with oil are suitable. They spin exceptionally fast and are easy to clean, but are more vulnerable to dirt damage.

2. Installation

You can generally press a bearing into place using your thumbs. Once correctly positioned, it aligns in line with the wheel core/hub. If the bearing protrudes from a corner, it is improperly installed and will get damaged during skating. For wheels with a metal core, bearing installation can be challenging; in this case, use a rubber hammer or a square piece of wood to tap it in.

Never use a metal hammer, as it will ruin the bearing and void your warranty.

Alternatively, lubrication may help in placing a bearing, but be sure to wipe off any excess afterwards.

3. Detailed Bearing Insights

Material

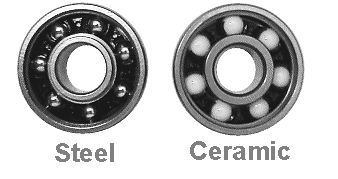

The material primarily determines a bearing's quality and longevity. Most bearings are composed of steel. Inexpensive options often use pressed sheet metal or hardened carbon steel, both of which do not promise durability.

Higher-quality bearings use genuine bearing-steel, such as chrome, titanium, or Swiss steel.

For ceramic bearings, typical in speed skating, the balls consist of industrial ceramic (Silicon Nitride). These ceramic balls resist rust and are more resilient than steel.

Generally, there's a direct relationship between cost and quality for bearings, and established brands are often reliable for producing sturdy and efficient bearings.

Precision/ABEC

Bearings are organized based on the industry-accepted ABEC specifications. This designation explains a bearing's ability to translate applied force. Higher ABEC ratings offer better precision, efficiency, and speed potential but do NOT inherently increase spinning speed. The ABEC rating doesn’t cover other crucial factors, like spacer and wheel precision or material quality. Over time, all bearings will experience precision loss due to wear.

Note that not every brand utilizes the ABEC scale (e.g. Bones), and other rating systems also exist.

ABEC denotes the Annular Bearing Engineering Committee.

Lubrication

Bearings may use oil or grease for lubrication. Under no circumstances should a bearing operate "out" of lubrication, as this could cause it to melt and either lose speed or jam altogether.

- Oil: Promotes higher speeds by reducing resistance in the lubricant. A thinner oil yields faster speeds but demands more frequent maintenance.

- Grease: More resistant to water and dirt compared to oil and requires virtually no maintenance. However, it does increase resistance, slightly reducing speed.

Important: Water can eliminate all lubrication! If this occurs and the water evaporates, your bearings may heat excessively and even melt, causing noise the next time they're used. Replacement is necessary if this happens. However, if bearings haven't been used in between, they might be recoverable with proper cleaning and oiling before the next use.

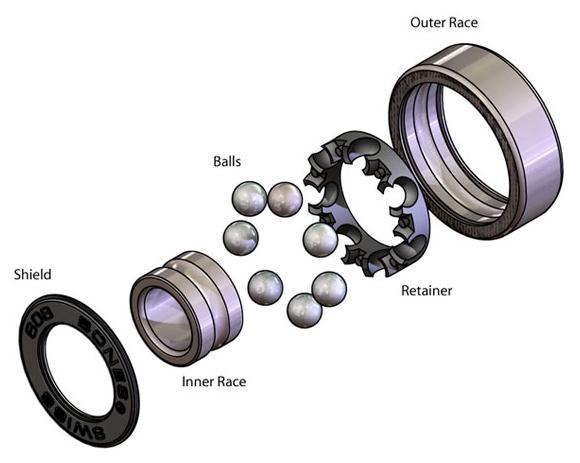

Shields/Seal

To protect bearings from dirt, sand, and water, a shield or seal is usually applied to one or both sides of the bearing.

- A Shield typically consists of metal and attaches to the outer ring, leaving a small gap to the inner ring (also known as a dustproof bearing). Bearings with shields exhibit minimal friction and rotate easily, enhancing speed. However, these do not fully protect against water and dirt.

- A Seal (illustrated below) comprises steel-reinforced rubber mounted to the outer ring and lightly touches the inner ring. This configuration offers superior protection and requires nearly no maintenance, albeit at a cost of increased friction and slightly reduced speed.

4. Standards and Bearing Precision Demystified

Several criteria contribute to ABEC grades, one being the eccentricity (roundness) of the track in the inner ring. The following table outlines the maximum eccentricity permissible.

| Type | mm | Inches |

| ABEC 1 | 0.0075 mm | (0.000295") |

| ABEC 3 | 0.0050 mm | (0.000197") |

| ABEC 5 | 0.0035 mm | (0.000138") |

| ABEC 7 | 0.0025 mm | (0.000098") |

| ABEC 9 | 0.0012 mm | (0.000047") |

Essentially, a higher ABEC rating signifies less deviation within the bearing components, resulting in enhanced power transfer to the wheel.

ABEC and ILQ are not directly comparable; ILQ is a trademark, while ABEC is a standard.

ABEC bearings gauge manufacturing precision but not performance under load conditions. On a scale akin to ABEC, Twincam evaluates ILQ bearings’ quality. However, ILQ bearings have 6 balls, unlike the 7 balls in ABEC bearings.

To clarify further, ILQ is not a standard like ABEC. ILQ should be viewed as a specialized bearing from a professional inline bearing maker, not as ideal for industrial machinery.

Bones bearings exclusively cater to skating and aren’t aligned with ABEC specifications.

Below is a vocabulary of bearings and shields (bearing type is generally printed on the bearing along with its dimensions, e.g.: 608ZZ).

608

- Standard bearing

- 22 mm outer diameter

- 7 mm width

- 8 mm inside diameter

688

- Mini/Micro bearing

- 16 mm outer diameter

- 5 mm width

- 8 mm inside diameter

Z

- Shield, 1 metal shield

- Open on one end for simple maintenance (always mount with the open side facing inside the wheel)

ZZ

- Shield, 2 metal shields

- The shields are secured with a small C-ring, removable for shield maintenance.

2RS/RS/RZ

- Seal, 2 steel-reinforced rubber seals

- Seals fit without C-rings. They can be removed carefully with a needle for servicing.

BRS

- Seal, 2 steel-reinforced rubber seals (non-contact)

- Seals fit without C-rings and offer superior water protection.