Guide to Purchasing Skateboard Trucks

Selecting skateboard trucks may seem daunting. However, buying from a reputable skateboard truck brand and ensuring the proper fit for your deck usually results in satisfaction with your purchase. If you select a complete skateboard, the trucks are already installed and dimensioned to complement the entire setup.

Overview

Understanding the Components of Skateboard Trucks

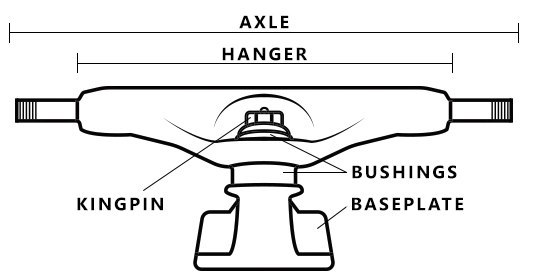

We begin by examining the fundamental aspects before delving into more detailed considerations. So, what precisely are skateboard trucks? In essence, they are the metallic T-shaped components that fasten to the underneath of your skateboard deck, supporting the wheels. They comprise two main pieces that pivot against each other: the baseplate and the hanger. These elements are secured together by a kingpin bolt, which also retains the bushings. Here are the main elements of a skateboard truck explained in depth:

Baseplate

Found as the flat metallic part, the baseplate attaches to the deck using 4 bolts. It uniformly disburses the skater's weight over the truck for stability and helps distribute landing impacts to the deck. The pivot cups located here enable hanger pivoting, which affects the fluidity of your turns. Acting as the crucial connection between the deck and the hanger, the baseplate remains integral to both the truck and the entirety of your setup.

Hanger

The largest element of a skateboard truck, the hanger, is a prolonged metal bar tapering to a triangular form near the pivot, which inserts into the baseplate's pivot cup. It directly affects rails, copings, and ledges during grind manoeuvres making it essential for performing grinding tricks.

Axle

The axle threads through the hanger's interior, with threaded ends for securing nuts that hold the wheels. Regular rail stands may wear down these threads, but rethreading tools can repair them. A T-tool with a built-in 5/16" axle re-threader can aid in fixing worn threads. Explore our selection of tools here:

Kingpin

This prominent bolt runs through the truck's centre, binding all parts together. The kingpin nut allows you to adjust how tight or loose your trucks are. Though susceptible to snapping under pressure, kingpins are replaceable.

Truck Bushings

Bushings are rubbery pads nestled between the baseplate and hanger, transferring pressure from your feet to the hangers. Hence, they significantly affect how nimble your setup feels. Their firmness influences your ability to turn:

- Hard bushings: Provide more stable and less flexible trucks, advantageous for shaky trucks though they demand more effort for turns.

- Soft bushings: Ideal for carving and cruising or for skaters enjoying loose, responsive trucks.

Discover more about installing skateboard bushings, or shop for new sets of bushings, washers, or other parts:

Now that you have a grasp of skateboard truck components, let's consider some important elements for picking suitable trucks for your setup.

How to Determine and Measure Skateboard Truck Sizes

Skateboard trucks have variable sizes concerning width and height. Below is a short guide to assist you in selecting an appropriate truck size.

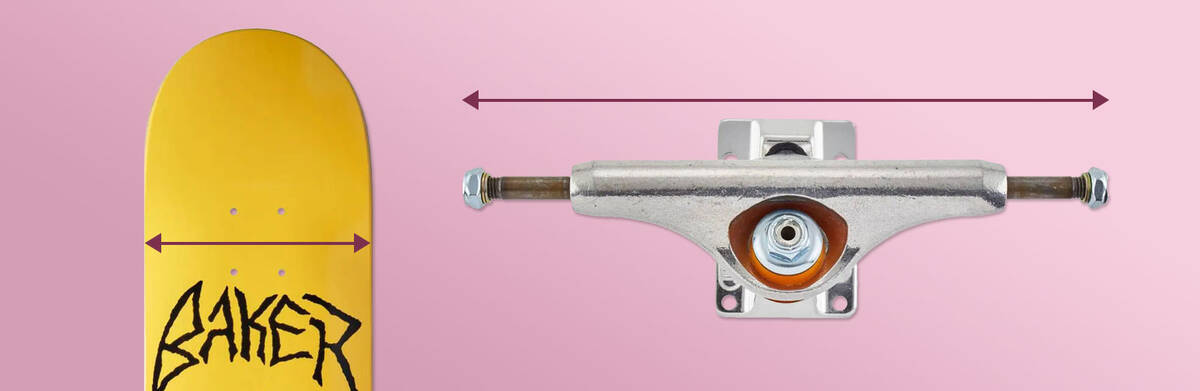

Width of Skateboard Trucks

Ensuring your truck's width matches your deck's width is crucial. In skateboarding, trucks that deviate in width from your deck can cause instability (if too narrow) or obstruct your shoes while pushing (if too wide) and hinder flip tricks.

Truck brands label their sizes based on hanger width, excluding the axles, but it’s the axle width that truly defines the truck's total width. To ease the selection, SkatePro provides axle width specifications, eliminating the need for converting manufacturer sizes to inches.

Height of Skateboard Trucks

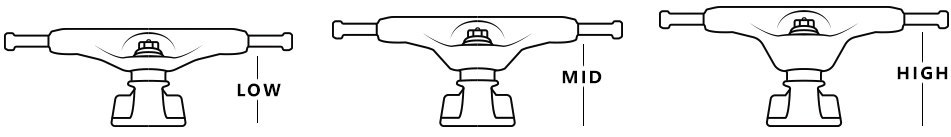

Truck height determines the vertical distance from the baseplate to the axle centre. When selecting truck height, contemplate the space between your deck, wheels, and the ground.

Trucks typically appear as high, medium, or low profiles, aiding your decision. Observe the key attributes below:

- Low Trucks (46-49 mm): Preferred for younger and beginner skaters due to improved control and stability, though wheels over 53 mm need risers to prevent deck contact.

- Mid Trucks (49.5-53.5 mm): Striking a balance between high and low, mid trucks fit most skaters. Avoid wheels above 56 mm without risers.

- High Trucks (53.5-60 mm): These provide more height for larger wheels and cruising setups. High trucks offer a wide platform for freestyle tricks and balance-intensive manoeuvres.

Our specifications list truck heights within our range.

Key Factors in Choosing the Right Skateboard Truck Height

The personal preference for truck height depends on your styling and physical traits. Here are some considerations for choosing between higher or lower trucks:

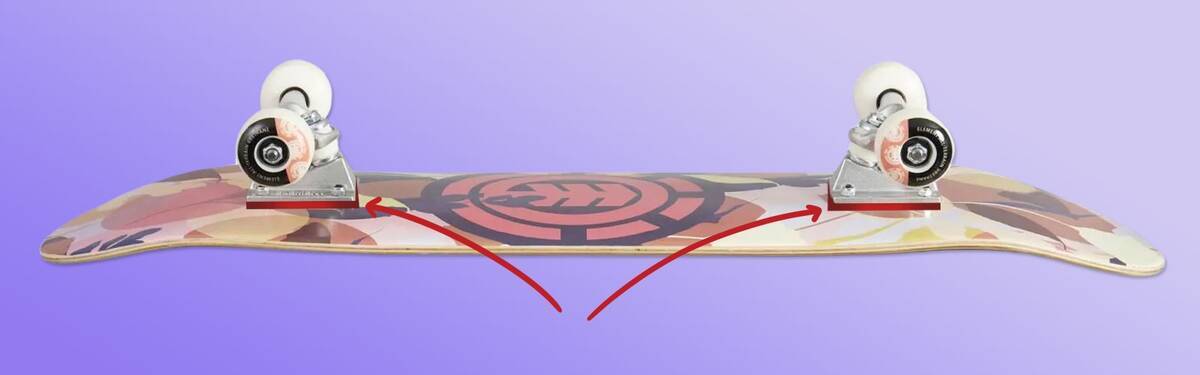

- Wheel clearance: Ensure enough space between the deck and wheels, imperative for smooth carving and deep turns. This is especially essential for those who prefer looser truck settings.

- Pop angle: Trucks with more elevation endow more leverage for high pops, whereas lower angles increase agility and swift response.

- Pushing: Higher trucks create a larger gap from your deck, potentially reducing push comfort over long distances.

- Tricks: Truck height can simplify or complicate certain tricks. High trucks aid balancing rail stands, while lower trucks favour quick flip manoeuvres.

- Truck weight: Larger trucks typically add more weight to your setup.

- Personal height: Taller individuals often find controlling a high truck setup easier compared to those with shorter stature.

Use Riser Pads to Modify Truck Height and Prevent Wheel Bites

Riser pads effectively mitigate wheel bites—when wheels strike the deck during turns. They afford extra height between the deck and wheels without the need for significant adjustments.

Consider riser pads if you wish to try larger wheels or relax your truck settings for improved flexibility.

For those addressing wheel bite issues or seeking enhanced deck performance, consider exploring our riser pad selection:

It's vital to use proper hardware when incorporating riser pads. For guidance on correct bolt lengths, refer to our guide:

Evaluating the Weight of Skateboard Trucks: Heavy vs. Light Options

Trucks largely contribute to your complete skateboard's weight. Recent innovations in truck design have focused on reducing this mass, employing hollow kingpins and axles, and testing alternative materials, all aimed at achieving this goal efficiently.

Currently, the Tensor Mag Light Series claims the title of “lightest trucks ever” on the market. Lighter trucks have undeniable benefits for tricks, even though weight variations might not stand out compared to other truck features.

When assessing truck weight, consider its relationship to truck dimensions. Larger trucks naturally weigh more, affecting wheel diameter and deck width choices.

Adjusting Skateboard Trucks: Loose vs. Tight

Altering your skateboard trucks' tension involves tightening or loosening the kingpin nut using either a skate tool or standard spanner. While tightening increases turn resistance, loosening allows for smoother, easier turns. This adjustment impacts your skateboard’s turnability, making it more rigid or flexible.

Your trucks' tightness influences your skateboard's turning dynamics, requiring experimentation to find an ideal setting. Carrying a skate tool enables testing and modifying settings on the go.

Reasons to tighten your trucks include:- Experiencing wheel bites while turning or during landings.

- Seeking a more stable popping motion.

- Feeling instability during high-speed runs or after landing tricks.

- Your front wheels lift while turning.

- You need to execute sharper turns.

- You desire more lateral freedom and feel restricted.

The turning and carving capability is influenced by the hardness of your bushings. Bushings come in varying hardness levels, typically assessed on the durometer scale. Bushings with a higher durometer are harder, resulting in tighter trucks. Browse our bushing options:

Steps to Fit Skateboard Trucks

To fit the trucks, you will need to use 4 nuts and 4 bolts for each. It's best to secure the bolts in a cross-diagonal sequence to uniformly tighten the baseplate across the surface.

We are available to assist you: