Purchasing Scooter Wheels

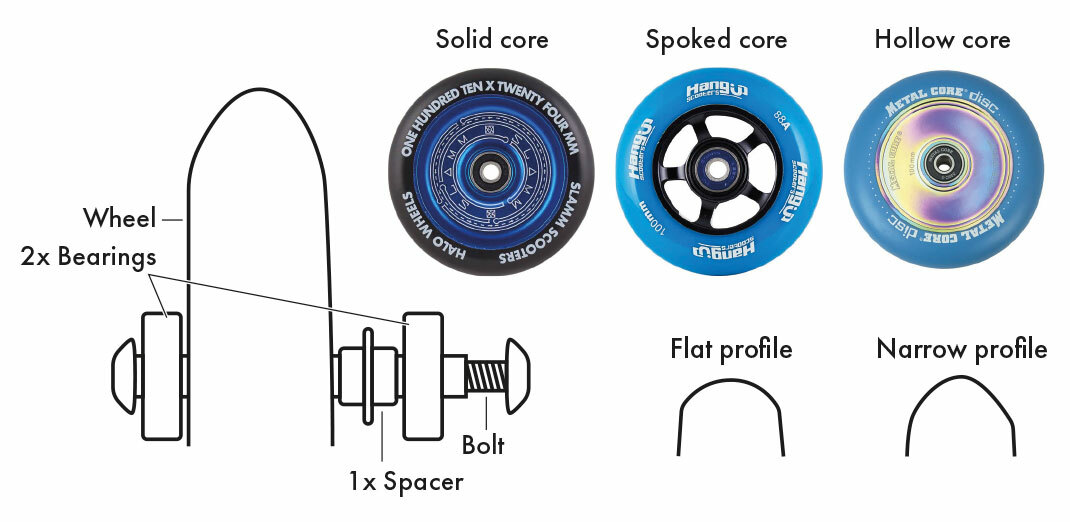

Each wheel necessitates 2x bearings and 1x spacer for proper functionality.

Wheels are constructed from varying materials, sizes, hardness levels, profiles, and diverse cores.

The accompanying illustration clarifies the distinctions.

Cores

- Solid core: A sturdy core ensuring maximal durability.

- Spoked core: This core features holes and cutouts, producing a lighter yet less robust wheel!

- Hollow core: Designed with a hollow interior for lightness, while still offering strength. (Not as strong as a solid core)

- Plastic core, not depicted: Plastic cores have a shorter lifespan and offer some flexibility.

- Honeycomb core, not depicted: Shares the hollow core concept but is further lightened by perforated holes.

Profiles

- Flat profile (this profile offers enhanced rubber strength and maximum grip)

- Narrow profile (a slender shape provides increased speed)

Hardness

- The durometer scale spans from 0-100a, with 100a representing the hardest. Most scooter wheels are rated at 85a.

- Hard wheels offer longevity, are slicker, but deliver increased speed!

- Soft wheels wear out more swiftly, yet provide excellent grip, making them ideal for parks and indoor settings.

- If wheel hardness isn't disclosed by the manufacturer, it's best to give it a try.

Inserting Bearings into the Wheel

- Bearings can be tricky to install into a wheel. We have provided a video guide for Inserting bearings into a scooter wheel with a metal core here.

Tips

- Ensure always to align bearings perfectly with the centre; misalignment can damage both bearings and the wheel centre.

- Using a hammer to insert the wheel or bearings voids the warranty and forfeits your right to claim damages.

- Some flat profile wheels may not be compatible with forks that have a pointed profile.

- Replace wheels when worn to avoid personal injury and to protect the Flex fender brake.

Warranty or Regular Wear?

Wheels designed for tricks often face extreme pressure and therefore exhibit limited longevity compared to other wheels.

Engaging in spinning tricks like a tail whip or a 360 results in sideways landings, stressing the wheels. Over repeated instances, wheels can suffer material breakage or detachment.

So how does one determine if damage qualifies for a warranty claim or if it's due to normal use?

Flat Spots

Hard braking that locks the brake can force a wheel against the asphalt and cause "flat spots." Such spots create straight lines on the wheel's curve, leading to a bumpy ride.

"Flat spots" do not constitute manufacturing defects and aren’t covered by the standard warranty. They result from incorrect scooter use, as no wheel is more resilient than asphalt.

Dehub

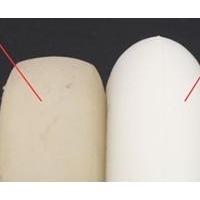

Pictured below are two wheels: the left one is relatively new with less than 30% wear, alongside a completely new wheel on the right.

If a wheel seems nearly new with minimal wear and has visible urethane separation from the hub, a production error could be the cause, depicted below:

Conversely, if the wheel has more than 40% wear and the urethane is still attached but damaged, it’s likely not a manufacturing flaw.

To determine if a production error exists, consult our claim guide for information needed to initiate a claim.

Return to Building a Custom Trick Scooter

Return to Stunt Scooters Discussed Here.